[wpdatatable id=17 table_view=regular]

Installation Tips for 6014 Bearing

The quality of the installation process of deep groove ball bearings determines the subsequent use effect of deep groove ball bearings. Therefore, the installation requirements of deep groove ball bearings are very high. Generally, small and medium-sized deep groove ball bearings can be installed using copper rods and manual hammering. The specific situation is that when the inner ring of the deep groove ball bearing has been installed and tightened, but the outer ring is relatively loose, a copper rod can be used to tightly fit the deep groove ball bearing. Use a hammer to directly hit the copper rod on the end face of the inner ring. The force is transmitted through the copper rod, and the deep groove ball bearing is slowly installed on the shaft.

When the inner ring of the deep groove ball bearing is large, you can use a copper rod to tap evenly and hard around the end face of the inner ring of the deep groove ball bearing. Do not tap only one side, nor use too much force. Tap symmetrically, tap gently and install slowly. , to avoid installing oblique cracking of deep groove ball bearings.

Deep groove ball bearings can also be installed using sleeve installation. It presses the sleeve directly on the end face of the deep groove ball bearing, and the knocking force with a hand hammer can be evenly distributed on the entire ring end face of the installed deep groove ball bearing. And it can be used in conjunction with a press, which saves effort and time in installation and ensures reliable quality.

If the deep groove ball bearing is installed on the shaft, the inner diameter of the sleeve should be slightly larger than the journal 1-4mm, and the outer diameter should be slightly smaller than the inner ring rib diameter of the deep groove ball bearing, or the thickness of the sleeve should be based on the thickness of the sleeve. It is equal to 2/3-4/5 of the thickness of the inner ring of the deep groove ball bearing, and both ends of the sleeve should be flat and perpendicular to the barrel body. If the deep groove ball bearing is installed in the seat hole, the outer diameter of the sleeve should be slightly smaller than the outer diameter of the deep groove ball bearing.

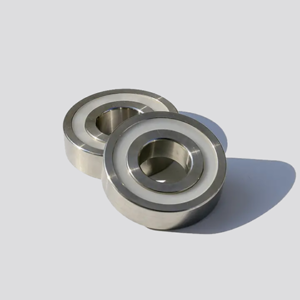

NSAR premium 6014 bearing is made in China and 6014 bearings Made of bearings steel,bearings steel with higher and more uniform hardness and abrasion resistance.The most rare is that of bearings steel with ultra-high hardness at the same time,have very strong elasticity.The assurance of hardness can prolong the service life of bearings.