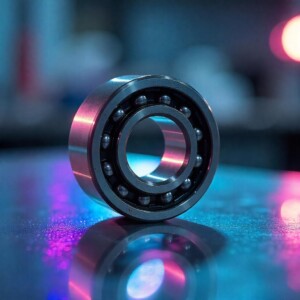

Bearings play a vital role in ensuring smooth operation of mechanical systems. However, over time, bearings are susceptible to damage, especially shock and vibration damage. This can have serious consequences, including equipment downtime, repair costs, and even catastrophic damage that poses a threat to safety.nsar provides high-quality deep groove ball bearings.

Brinelling refers to permanent indentation damage that occurs on the surface of a bearing raceway when subjected to excessive static or shock loads. This damage usually appears as small, evenly spaced indentations that match the spacing of the bearing rolling elements. Brinelling can be caused by improper installation techniques (such as hammering the bearing into place with a hammer) or strong shocks during transportation or operation.

There are two main types of brinelling: true brinelling and false brinelling. True brinelling is caused by high static loads or shocks, while false brinelling is caused by vibration acting on a fixed bearing, which is usually caused by improper handling or storage. In both cases, the damage creates stress concentrations that, if not addressed, can cause premature bearing failure. Understanding how to identify and prevent brinelling is critical to extending equipment life and avoiding costly downtime.![]()

Excessive static loads:

Heavy loads acting on stationary bearings for long periods of time can cause permanent deformation.

Shock loads:

Dropping equipment or machinery during handling or subjecting it to sudden, strong impacts during operation can cause indentations.

Improper installation:

Excessive force applied during bearing installation or removal, especially when pressing on the outer race when the inner race should be, can damage the raceways.

Shock loads:

Sudden, strong impacts can cause rolling elements to leave indentations in the raceways, creating brinelling marks.

Vibration of stationary bearings: When a bearing is subjected to vibration while stationary, the rolling elements oscillate slightly, causing fretting corrosion and indentations similar to brinelling.

Poor lubrication: Inadequate lubrication exacerbates the effects of vibration and fretting, making the bearing more susceptible to false brinelling. Oscillating motion: Small oscillations can also cause false brinelling.

NSAR Bearings strictly controls every process of bearing production, and each step is precisely dimensioned to ensure the smooth production of our high-quality bearings. Work with us to customize the bearing you want.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy