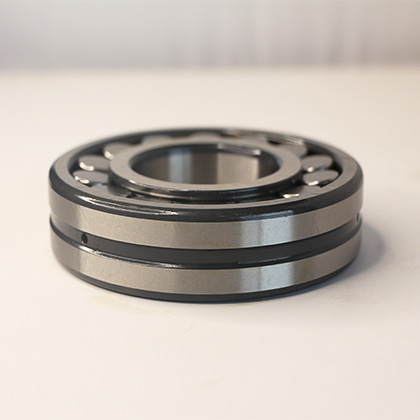

Double row spherical roller bearings consist of two rows of rollers that share a common spherical groove on the outer ring and two separate grooves on the inner ring that can be tilted relative to the bearing axis.

Categories: Spherical Roller Bearings

Double row spherical roller bearings consist of two rows of rollers that share a common spherical groove on the outer ring and two separate grooves on the inner ring that can be tilted relative to the bearing axis. This gives spherical bearings an excellent combination of design features that cannot be replaced in many special applications. This type of bearing is self-selecting and therefore less susceptible to shaft misalignment than bearing and shaft deflection or curvature. Double row spherical roller bearings are available with cylindrical bores and tapered bores with tapers of 1:12 or 1:30. The bearings are mounted directly on the cylindrical shaft or on a bushing against a tapered shaft. Click here to see our current product models.

Double row spherical roller bearings are suitable for larger radial loads. They can also accommodate some axial loads in either direction. They are suitable for moderate speeds. Double row spherical roller bearings have spherical raceways in both rows of rollers in the outer ring. Therefore, for simpler and more efficient lubrication, double row spherical roller bearings (except type 213) can also be equipped with a peripheral lubrication groove and a lubrication hole in the middle of the outer ring. Most bearing types are produced with this structure. For larger types, lubrication can be provided through the outer ring and the inner ring.

C, CD – stamped steel cage

EA – stamped steel nitrided cage without guide rings. The bearing has larger rollers and an optimized internal design for higher speeds and higher loads

CA, M – machined brass cage guided by the inner ring (higher speed and load capacity)

Double row spherical roller bearings are available with a cylindrical or tapered bore. Bearing types 240… and 241… have a tapered bore with a bore taper of 1:30 (additional designation K30). For all other tapered bore types, the bore taper is 1:12 (K). Double row spherical roller bearings are mounted directly on tapered or cylindrical shafts using adapters or withdrawal sleeves.

Spherical roller bearings are typically used for heavy loads and where they have the advantage of being self-aligning.

They are self-aligning over a wide range and can tolerate minor misalignment.

Our spherical bearing design is engineered to provide superior load distribution and enhanced longevity in demanding environments.

| Product Name: | Spherical roller bearing 22222E1 ,22217EAE4, 22220E, 22224CC/W33 by chrome steel material | Brand: | NSAR,3D, OWO, NASA, CBQ, OEM brand |

| Model Number: | 22222E1, 22220E, 22224CC/W33, 22217EAE4 | Certificate: | ISO9001-2015 |

| Original: | China | Structure: | Spherical roller bearing,spherical bearing, roller bearing, roller bearing types |

| Number of Row: | Double Row | Model Number: | 22220E, 22222EAE4, 22224E1,23020CC/W33,23220E1, 24030E1, BS2-2224-2CS |

| Bore size: | 20-260mm | Bearing Material: | Gcr15 |

| Bearing Hardness: | 61-63HRC | Cage Type: | CC, E, E1, EAE4, |

| Cage Material: | Steel | Seals Type: | Open, sealed |

| Precision Rating: | P0 P6 P5 | Clearance: | C0, C3, C4, C5 |

| Applicable Industries: | Industrial bearing, Papermaking machinery, deceleration devices, railway vehicle axles, rolling mill gear box housings, rolling mill rollers, crushers, vibrating screens, printing machinery, woodworking machinery, various types of industrial reducers, vertical self-aligning spherical bearings. |

||

NSAR Spherical roller bearing is in the two race between inner ring and groove for spherical outer ring, assembly cylindrical roller bearing. This kind of bearings have single row and double row bearings. Nd they have E, CA, CC, MB model, etc.This kind bearings with high speed, low noise, heavy load, high temperature resistance, corrosion resistance, long life, good stability, etc.

Spherical Roller Bearings with hardened steel cages deliver greater fatigue strength, increased wear-resistance and tougher protection against shock and acceleration.Spherical Roller Bearings with brass cages provide extra strength and durability in the most unrelenting conditions, including extreme shock and vibration, high acceleration forces and minimal lubrication.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy