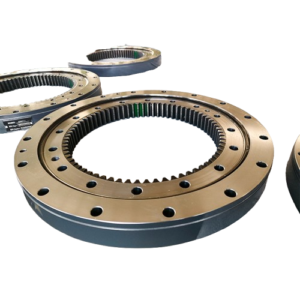

A slewing bearing is a bearing that allows rotational motion while supporting heavy loads such as axial forces, radial forces and tilting moments. It usually consists of two rings (inner and outer) separated by rolling elements such as balls or rollers. These components allow for smooth rotation, and some slewing bearings are equipped with gear mechanisms for transmitting torque.

Categories: Slewing Bearings

A slewing bearing, also known as a turntable bearing, is a machine element that absorbs all axial and radial forces and the resulting tilting moments in a single, self-retaining and ready-to-mount bearing unit.

The overall design of the product, including the inner and outer rings, gear cutting, rolling elements and mounting holes, enables it to transfer the applied loads while enabling smooth rotation while maintaining a compact footprint. Slewing bearings enable and facilitate rotary motion in wind turbines, excavators, cranes and tunnel boring machines, among others. Slewing Bearing offer many advantages over other solutions, including a significantly smaller footprint, lower weight and, in most cases, greater cost-effectiveness.

Slewing bearing basic specifications

| Item No. | 071.22.372 | Diameter | 278X504X95mm |

| Material | 50Mn, 42CrMo, Stainless Steel | Work Temperature | -20℃~+70℃ |

| Brand | NSAR,3D, OWO, NASA, CBQ, OEM Brand | Structure | Double Row Ball Slewing Bearing |

| Certificate | ISO 9001-2015 | Original | China |

| Application | Cranes, Mining Equipment, Excavators. etc. | Customed Production | Available By Drawing Pictures |

Single Row Ball Type (01, HS, Q), Dowble Row Ball Type (02), Three Row Roller Type (13), Single Row Cross Roller (11), Double Line Ball Type (07), Ball Roller Combined Type

We manufacture standard and custom slewing bearings in a variety of designs with outer diameters from 0.1 to 18 meters to meet the needs of specific applications.

For more information on NSAR slewing bearings, click here.![]()

Many application requirements influence the selection of the right slewing bearing. These considerations include speed, contamination protection, precision, frictional resistance, and the temperature range of the operating environment. NASR manufacture small single-row ball slewing bearings for light applications, large triple-roller slewing bearings for demanding heavy-duty applications, and gear bearings for everything in between.

High-endurance slewing bearings can help improve turbine performance by controlling the movement of the blades and nacelle

Wind turbines must cope with many extreme conditions, including severe weather and huge loads. Their remote locations and the need to generate more electricity make their design more challenging. High-endurance slewing bearings were developed to meet these challenges.

Increase productivity and improve operator comfort

The tough conditions and heavy workloads of the mining industry present real challenges for excavators, bucket wheel excavators and stacker/recyclers. Slewing bearing solutions are critical to the performance and reliability of these applications.

Slewing bearings are widely used in heavy equipments, such as hoisting machinery, mining machinery, construction machinery, port machinery, ship machinery and large-scale slewing devices of high-precision radar machinery and missile launchers.

Material quality: Bearings made from high-grade materials such as stainless steel or specially treated alloy steels tend to cost more due to their increased durability and performance.

Size and dimensions: Larger bearings or bearings with custom dimensions may result in higher costs due to manufacturing complexity and the amount of material required.

Precision and tolerance levels: Bearings that require high-precision machining are often more expensive due to the technology and processes involved in their production.

Brand reputation: Well-known brands may charge a premium for their slewing ring bearings to reflect their reliability, quality assurance, and after-sales support.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy