Needle roller bearings, precision-engineered components, are widely used in various industries due to their ability to withstand high radial loads in a limited space.NSAR offers a variety of safe and cost-effective customized packaging solutions for bearings to ensure the most necessary protection and preservation of our products.

Categories: Needle Roller Bearings

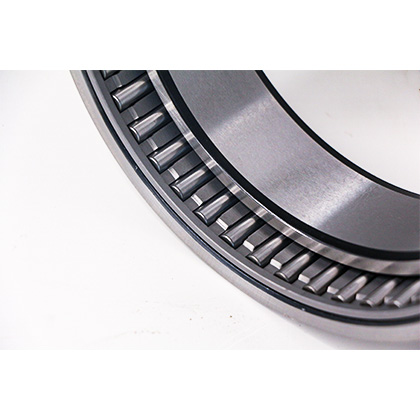

Needle roller bearings, precision-engineered components, are widely used in various industries due to their ability to withstand high radial loads in a limited space. The correct selection of needle roller bearings is essential to ensure the optimal performance and service life of mechanical equipment.

| Item: | NA4830 | Brand: | NSAR,3D, OWO, NASA, CBQ, OEM brand |

| Type: | Needle bearing, needle roller bearing | Certificate: | ISO9001-2015 |

| Original: | China | Material: | Chrome Steel |

| Inner Diameter: | 150mm | Outer Diameter: | 190mm |

| Height: | 40mm | Bearing Material: | Gcr15 |

| Bearing Hardness: | 61-63HRC | Cage Type: | CC, E, E1, EAE4, |

| Precision Rating: | P0 P6 P5 | Series: | NA… |

| Application: | Machine tools, motorcycle gearboxes, textile machinery, printing machinery, pasture machinery, agricultural machinery, rollers for CNC equipment guide rails, conveyor equipment, etc. | ||

The needle roller bearing size chart is a comprehensive reference guide that provides important information about different types and sizes of needle roller bearings. It generally includes key parameters such as inner diameter, outer diameter, width and load capacity. The size chart may also provide other details such as limiting speed, tolerance class and available variations of cage design and materials.

The structure of needle roller bearings is diverse, and the scope of application is also different as follows:

1. Needle roller bearings with drawn outer ring. This kind of bearing has two types of perforated type and sealed type. The drawn outer ring needle roller bearing has no inner ring, and the needle directly contacts the surface of the shaft, so the machining accuracy and heat treatment hardness of the shaft should be the same as the bearing inner ring.

![]()

Scope of application: Drawn cup needle roller bearings with cage are suitable for high speed and heavy load, and are mostly used in gearboxes or textile machinery of machine tools, automobiles and motorcycles.

Drawn cup needle roller bearings without cages are suitable for oscillating working conditions under heavy loads because they are filled with needle rollers. Such as the frame of the aircraft, the shaft end of the main wing of the missile, etc.

Drawn cup needle roller bearings without cages are suitable for oscillating working conditions under heavy loads because they are filled with needle rollers. Such as the frame of the aircraft, the shaft end of the main wing of the missile, etc.

2. Solid ring needle roller bearings. Commonly used solid ring needle roller bearings are NA type and RNA type.

Scope of application: It is mostly used in machine tools, automobile gearboxes, and its advantages are small radial cross-sectional size and large radial load.

Standard solid ring needle roller bearings have cages, so the speed is higher and can meet the requirements of machine tools and gearboxes.

3.Caged needle roller bearings are suitable for printing machinery, pasture machinery, agricultural machinery, rollers for NC equipment guide rails, conveyor lines, etc.

4. Needle roller and cage assembly. The needle roller and cage components are actually needle roller bearings without ferrules. The scope of application: mostly used for the large and small ends of connecting rods for automobiles and motorcycles.

As the internal temperature of the air box rises, the bearings must be resistant to high temperatures.

Customized Bearing Packaging

NSAR offers a variety of safe and cost-effective customized packaging solutions for bearings to ensure the most necessary protection and preservation of our products. Our goal is to provide you with packaging that is suitable for your shipping and production needs.

View needle roller bearing articles:

Copyright © NSAR Bearings. All rights reserved. Privacy Policy