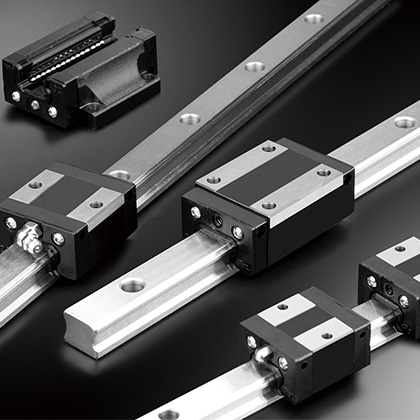

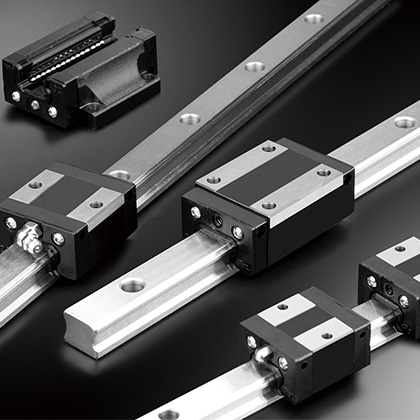

Linear guides provide linear motion by recirculating rolling elements between profiled rails and bearing housings. Superior load capacity and precise control are achieved using NSAR’s linear guideways.

Categories: Linear Guideway

HGH series linear guides are designed for heavy load and high precision applications. HGH linear guides use a four-row arc contact design to provide uniform rated loads and high rigidity in all directions, making them ideal for applications that require high precision and stability under heavy loads.

Linear guides provide linear motion by circulating rolling elements between profiled rails and bearing housings. The coefficient of friction on linear guides is only 1/50 compared to conventional slides. With these features, linear guides can achieve high accuracy and greatly improved movement precision when carrying loads in all directions. Linear Guideway Supplier offers a wide range of linear guide series, each with different options for size, load capacity, accuracy, etc.![]()

Linear ball bearing and guideway assemblies are the most extensive and complex components in the range of monorail guide systems. They are used in situations where linear guide systems with high load capacity and rigidity must move heavy loads with high running and positioning accuracy and low friction. The guide systems are preloaded and suitable for long travels without restrictions.

Lightweight and backlash-free movement

Because linear guides are rolling guides, there is no backlash and movement is lighter than with sliding guides.

Infinite linear motion is possible

Rolling guides, such as cross roller guides and ball guides, have limited strokes, but the balls of linear guides can circulate infinitely, which means that the stroke can be extended to the length of the guide.

High allowable load

The raceways of linear guides are curved grooves, and the balls are in surface contact with the raceways. The allowable load is about 13 times higher than that of point contact guide components such as linear bushings, so linear guides can achieve the same allowable load as point contact type guides with a more compact design.

Linear Guideway Specification

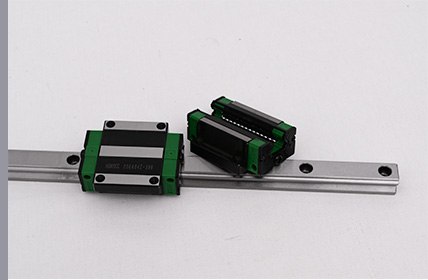

| Product Name: | HGH15CA | Brand: | NSAR,3D,OWO,CBQ,NASA |

| Certification: | ISO9001-2015 | Country of origin: | China |

| color: | The slider dark green | Nature: | For supporting body movement direction |

| Material: | S55C | Model: | HGH15CA |

| Slider material: | 20CrMo (Guide material:S55C, Slider material:20CrMo) | Function: | To provide bearing surface smooth movement |

Linear guides are mainly composed of three parts: a moving table, a track for the support table to move, and balls. By installing a mechanism that circulates the balls, linear motion can be achieved.

Linear guides with ball and roller bearings are a must-have in many industries. Since they are available in a variety of sizes and capacity levels, they can be used in many different applications.

The linear guides provided by NSAR feature hardened raceways, high load capacity, and self-aligning features. Our linear guide systems are also able to work in dirty environments. So, whatever your needs for linear motion guides, you’ve come to the right place.

The role of linear guides is to guide linear motion easily and smoothly while bearing loads, allowing machines to operate accurately and efficiently. They are indispensable linear components in devices such as machine tools and semiconductor manufacturing equipment. Recently, they are also used in railway vehicles, buses, automatic doors, anti-vibration systems and other livelihood fields.![]()

MOQ:1 set

Price:USD 1.1-USD3.2/Set

Payment:T/T, Irrevocable letter of credit at sight, paypal, western union

Supply Ability:1000000 sets/per month

Shipment time:7-50 working days once getting customer’s confirmation.

Packing:single box/tube/industrial packing then cartons,pallets for sea shipment.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy