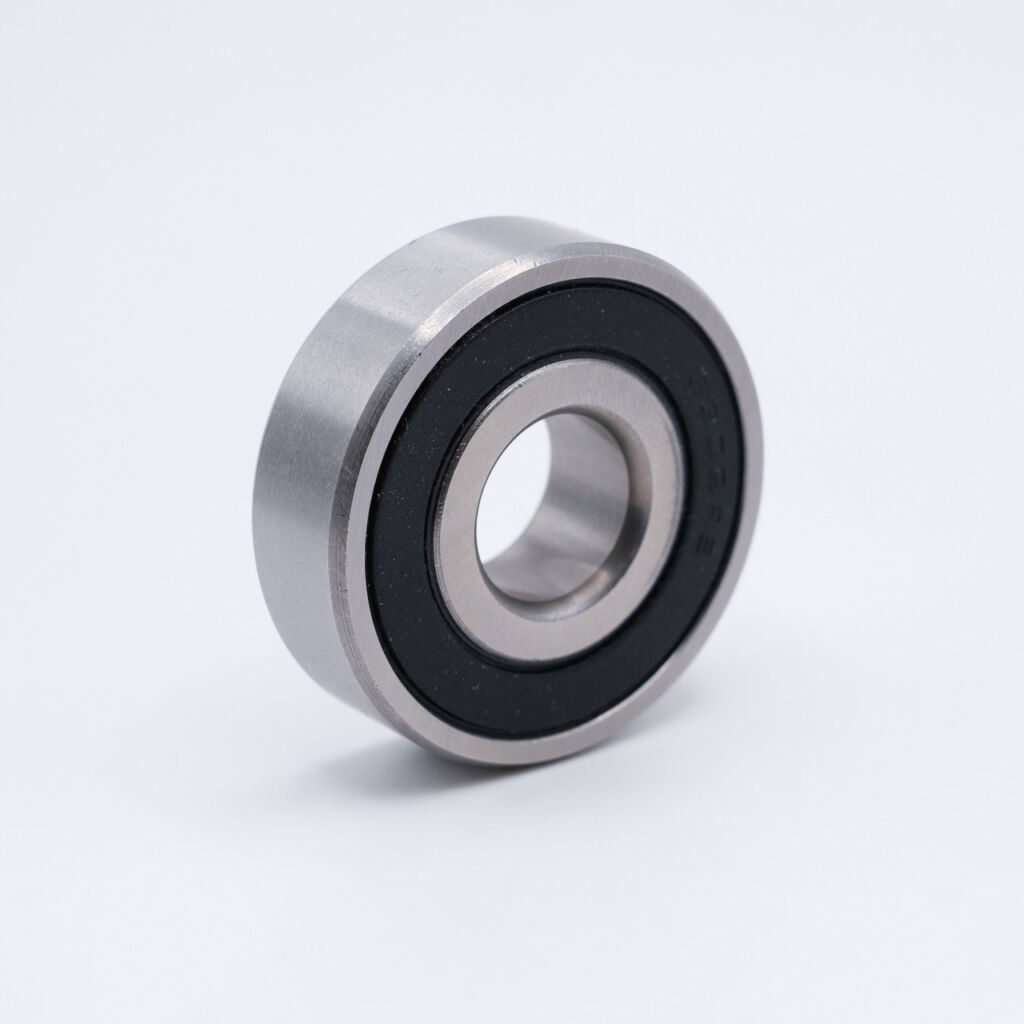

Categories: 6300 Series Bearing

[wpdatatable id=45 table_view=regular]

The purpose of deep groove ball bearings lubrication is to form a thin oil film on the surface of the ring and rolling elements to prevent direct metal contact, thereby avoiding wear and shortening the bearing life. In addition, the lubricant reduces the noise and friction during bearing operation, improving the efficiency of the bearing. operating characteristics, in addition to wear protection and heat dissipation functions.

Commonly used lubricants include lubricants and greases. The correct lubricant should be selected according to different applications and different environments to optimize bearing performance.

Grease lubricants are easier to use than oil lubricants because of their viscosity, they are more durable and require only simple sealing equipment. Grease is difficult to change because common practice is to force the grease into the device, allowing the new grease to squeeze out the old grease. Generally speaking, grease with low viscosity base oil is more suitable for low temperature and high-speed operation, while grease with high viscosity base oil is suitable for heavy loads.

Oil lubrication is more suitable for use under high-speed and high-temperature conditions, as it can effectively take away the heat during bearing operation.

The viscosity of oil determines the effectiveness of oil lubrication. If the viscosity is too low, the oil film formation will be insufficient; if the viscosity is too high, the viscous resistance will increase and the temperature rise will increase. Generally, the greater the rotation speed, the lower the viscosity of the lubricating oil; the greater the load, the higher the viscosity of the lubricating oil.

NSAR are widely used in household appliance. micro-motors electrical tools garden machinery, motorcycles,automobiles,medical equipment, sports machinery, textile machinery and agricultural machinery.

The bearings we manufacture are all low noise,low vibration,low friction, high precision, high sealed,high turning speed and long life.

Quality is the key point for the NSAR. bearing’s growth and development, which always regards the improvement of high quality and service as the long-term-development strategy. NSAR has passed IS09001: 2000, 1S09001: 2008, and will struggle for the NSAR in long term.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy