Product List

Send your inquiry

Contact Us

OUR QC

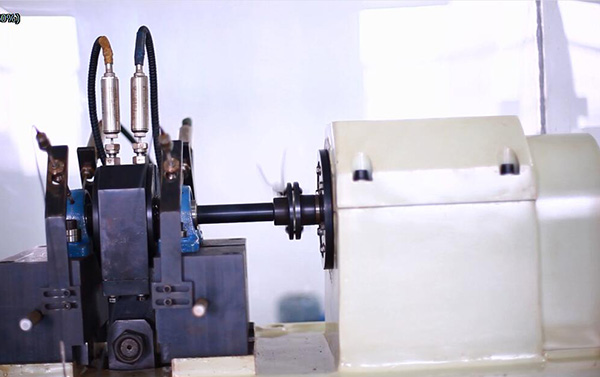

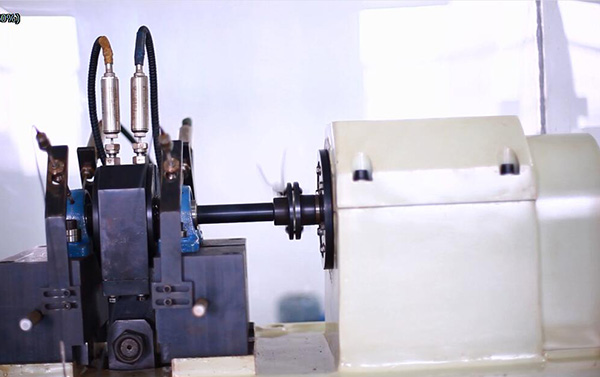

Stable quality comes from our advanced manufacturing equipment, optimized production process, the strict control for each production process, strict quality testing, and excellent product packaging.

Forging. Turning. Heat-treatment. Grinding. Super-finishing.Painting. Each process is meticulous. Cage, ball, roller, grease, seal cover - each accessory strictly checked. Assembly, cleaning, lubricating, sealing, testing on fully automated assembly line and careful packaging, ensures that NSAR bearings were researched and developed by DFL Company with the excellent character of stable quality, cost-effective and long life stability, and selling well in the global market.

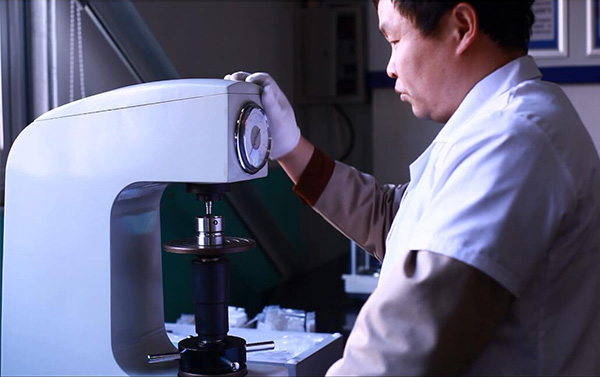

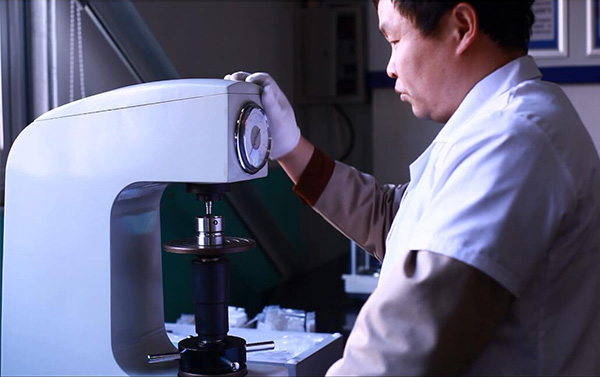

NSAR brand bearings dimension accuracy, vibration and noise are 100% tested. For length measuring,rough sketch, roundness, metallographical, roughness, Hardness,life expectancy, tensile strength, corrosion resistance for batch testing.

Forging. Turning. Heat-treatment. Grinding. Super-finishing.Painting. Each process is meticulous. Cage, ball, roller, grease, seal cover - each accessory strictly checked. Assembly, cleaning, lubricating, sealing, testing on fully automated assembly line and careful packaging, ensures that NSAR bearings were researched and developed by DFL Company with the excellent character of stable quality, cost-effective and long life stability, and selling well in the global market.

NSAR brand bearings dimension accuracy, vibration and noise are 100% tested. For length measuring,rough sketch, roundness, metallographical, roughness, Hardness,life expectancy, tensile strength, corrosion resistance for batch testing.