Needle bearings, also known as needle roller bearings, are essential components in many industrial and automotive systems. They are designed to handle high radial loads within a compact design, making them ideal for applications where space and weight are limited. However, choosing the correct size of a needle bearing is crucial for ensuring performance, longevity, and reliability. Here’s a complete guide on how to size a needle bearing for your project.

1. Understand Your Application Requirements

Before selecting a bearing, clearly define your working conditions:

Load type and magnitude: Determine if the bearing will handle radial, axial, or combined loads.

Speed: Record the operating speed (in RPM).

Required service life: Estimate how long the bearing must last in hours or revolutions.

Mounting space: Note the available bore, outer diameter, and width.

Operating environment: Consider temperature, contamination, and lubrication conditions.

These factors will serve as the foundation for accurate bearing selection.

2. Calculate the Equivalent Bearing Load

For most needle bearings, the radial load (Fᵣ) is the main factor to consider.

If only radial forces are applied:

P=Fr

If both radial and axial loads exist, the equivalent load should be determined using manufacturer load factors:

P=XFr+YFa

where X and Y are factors based on bearing type and load direction.

3. Determine the Required Bearing Life

The bearing’s basic rating life (L₁₀) represents the number of revolutions a bearing can endure before fatigue occurs in 90% of identical units.

To calculate L₁₀ in millions of revolutions:

where:

n = speed in RPM

T = desired life in hours

4. Select the Dynamic Load Rating (C)

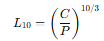

Needle bearings are a type of roller bearing, so the life equation uses an exponent of 10/3:

Rearranging for C:

C=P×(L10)1/(10/3)

Choose a bearing whose dynamic load rating (C) from the manufacturer’s catalogue is equal to or higher than this calculated value. Always verify that the static load rating (C₀) also meets your design requirements.

5. Check Dimensions, Fits, and Lubrication

After determining the load rating, ensure the bearing dimensions match your housing and shaft tolerances. Proper fit and lubrication are vital to prevent wear and overheating. If the bearing operates under shock loads or poor lubrication, apply safety factors or select a higher-capacity design.

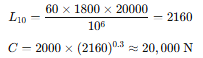

6. Example: Quick Calculation

Radial load: 2000 N

Speed: 1800 RPM

Desired life: 20,000 hours

A needle bearing with a dynamic load rating of 20 kN or higher would meet this application’s needs.

7. Why Work With DFL NSAR

At DFL NSAR, we supply a wide range of needle roller bearings with reliable quality, competitive prices, and fast delivery from our overseas warehouses in the United States.

Our technical team can assist you with:

Bearing size calculations

OEM brand cooperation

Custom bearing design and production

Whether you need standard needle bearings or custom solutions, DFL NSAR provides durable products and professional support to help your machines run smoothly.

Sizing a needle bearing correctly ensures optimal performance and prevents premature failure. By analyzing the load, speed, and life requirements, you can select the most suitable bearing for your application. For technical support or bulk purchase inquiries, contact DFL NSAR — your trusted needle bearing manufacturer and supplier.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy