Think of the fantastic network of machines that surround us every day, from the spinning fans that help us cool down to the engines that power cars. At the heart of many of these wonders lies a hidden gem: the deep groove ball bearing.

These simple elements are, in fact, the driving force of much of the mechanical environment, allowing for particularly efficient and frictionless rotation. But what goes behind the making of these incredible products?This article provides a detailed view of how these components are assembled, giving you a profound knowledge of the making process.

What is a Deep Groove Ball Bearing?

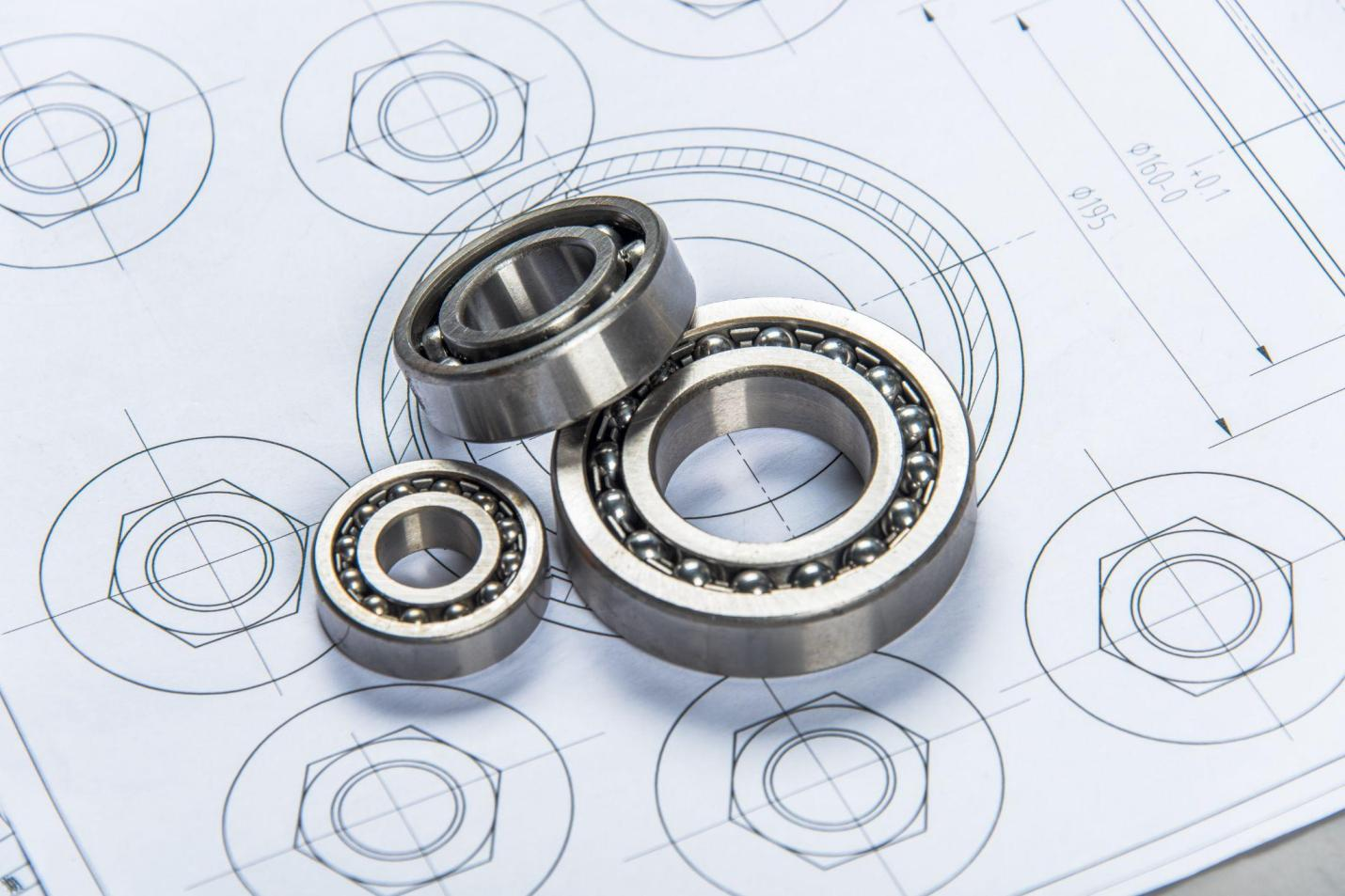

Now that we want to talk about assembly, let us first understand the deep groove ball bearing.

A deep groove ball bearing is a rolling-element bearing comprising deep and symmetric race grooves on the inner and outer rings. These grooves make the bearing capable of supporting radial and axial loads in both directions, thus improving its flexibility.

![]()

Deep Groove Ball Bearings are used for:

●Electric Motors: Because of their high speed and low friction, they are suited for electric motors.

●Automotive Industry: Applied in wheels, transmissions, gears, and other automobile parts.

●Home Appliances: These are used in washing machines, ceiling fans, etc.

●Industrial Machinery: Used mainly in conveyor systems, pumps, and any industrial equipment.

●Aerospace: Mainly used in aircraft engines and other modes of aerospace.

Deep Groove Ball Bearing Types

Several varieties of deep groove ball bearings exist to meet the needs of different applications across different industries. Each type provides features best suited for the intended purposes, making the system efficient and highly dependable.

●Open Bearings: These are the most basic type and often the most straightforward design with no seals or shields. They allow maximum bearing component exposure, facilitating lubrication and even inspection.

●Sealed Bearings: In cases where dust, dirt, or moisture may be an issue, the sealed bearings should provide the best fit. These bearings have a seal on one or both ends, thus preventing debris intrusion into the bearings.

●Shielded Bearings: Shielded bearings offer a middle ground between open and sealed designs. They have thin metal plates on one or both sides that help prevent dust and large particles from entering.

Behind the Scenes – Assembling a Deep Groove Ball Bearing

Deep groove ball bearings look pretty simple in their construction, perhaps the most precisely constructed bearings. Let’s peek behind the curtain and witness how these metals are transformed into fully functional parts to drive millions of machines.

1.A Clean Start

The process starts with cleaning all parts – the inner and outer rings, the balls, and the cage. Cleaning is critical since even particles too small to be seen with the naked eye can cause wear and abrasion.

2.The Lubrication Layer (Optional)

Depending on the application, a thin lubricant layer must be applied to the bearing components. This lubricant functions as a protective film to reduce friction and extend the life of the bearing.

3.Caging the Components

The tiny balls are put neatly inside the cage. The cage, usually made of steel, brass, or polyamide, separates the balls, minimizing the friction and wear between the balls.

4.Inner Ring Assembly

The loaded cage and balls are carefully placed within the inner ring raceway. This step should be carried out carefully to position the balls correctly and initiate a smooth rolling movement.

5.Outer Ring Assembly

The final step is to assemble the cages and press the outer ring onto them. This helps achieve a close fit that optimizes the performance of the bearing. However, if too much pressure is applied, the bearing can be deformed, so precision management is required.

6.Quality Check – Ensuring Peak Performance

After the assembly, the bearing is tested through several rigorous tests. Engineers scrutinize the bearing for function and wear, dimensional accuracy, and performance overloads applied to it. All bearings that fail to meet these specifications are excluded to ensure the premium quality of the final product.

Perfect Deep Groove Ball Bearings from NSAR

Discover the excellence of deep groove ball bearings from NSAR Bearings, designed for various uses ranging from lawnmowers and cars to multi-million dollar machines.

Our premium bearings increase axial and radial load ratings while lowering noise, vibration, and friction. They are renowned for their improved durability and ease of installation. With over two decades of manufacturing experience, we provide our clients with total flexibility and personal service.

Visit NSAR Bearings to explore our range and meet your large-scale needs with our 6012, 6000, 6200, and 6300 series bearings. With NSAR Bearings, you can be confident you are using quality bearings that will help you keep your machines running smoothly for many years.