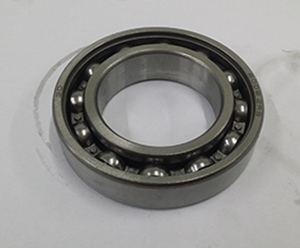

Deep groove ball bearings China

NSAR, a professional deep groove ball bearings supplier in China, provides a broad variety of deep groove ball bearings with best customer service and quality assured. With more than 20 years deep groove ball bearings manufacture experience, our deep groove ball bearing has been exported to United States, Canada, Mexico, Brazil, Argentina.NSAR can satisfy your bulk deep groove ball bearing customization needs,We provide 6012 bearing and 6000 bearings series and 6200 bearings series and pillow block ball bearings and 6300 bearing,you can products download.

Deep groove ball bearings are a type of rolling-element bearing widely used in various mechanical and electromechanical systems. Here are some key characteristics and features of deep groove ball bearings:

1.Load Capacity: These bearings are capable of handling moderate to high radial loads and axial loads in both directions. The deep raceway grooves distribute the load evenly across the balls, enabling efficient load distribution and improved load-carrying capacity.

2.Design: Deep groove ball bearings typically consist of an inner ring, an outer ring, a cage, and a set of balls. The inner and outer rings have deep raceway grooves that enable the bearings to accommodate both radial and axial loads.

3.Versatility: Deep groove ball bearings are versatile and can be used in a wide range of applications, including electric motors, pumps, fans, transmissions, automotive components, household appliances, and industrial machinery.

4.Low Friction: Deep groove ball bearings are designed to minimize friction between the moving parts, resulting in smooth and efficient operation. This low-friction characteristic makes them suitable for high-speed applications where energy efficiency and reduced heat generation are important.

5.Quiet Operation: Deep groove ball bearings operate quietly, making them suitable for applications where noise reduction is desired, such as in office equipment, consumer electronics, and automotive components.

6.Sealing Options: These bearings can be equipped with various sealing options, such as shields or seals, to protect against contaminants and retain lubrication. Sealed bearings offer improved protection against dust, moisture, and other contaminants, extending the service life of the bearings.

7.Standard Sizes: Deep groove ball bearings are available in a wide range of standard sizes and configurations, making them easily interchangeable and compatible with components from different manufacturers. This standardization simplifies sourcing, installation, and maintenance processes for end-users.

8.Temperature Range: They can operate effectively across a wide temperature range, from cryogenic temperatures to elevated temperatures, depending on the materials used and the specific design of the bearing.

9.Cage Design: The cage in deep groove ball bearings helps to maintain proper spacing and alignment of the balls, ensuring smooth rotation and preventing contact between adjacent balls. Common cage materials include stamped steel, brass, and engineered polymers, each offering unique advantages in terms of strength, temperature resistance, and friction reduction.

10.Materials: Deep groove ball bearings are commonly made from high-quality steel, such as chrome steel (52100), which provides excellent strength and durability. In some cases, alternative materials such as stainless steel or ceramic are used for specific applications requiring resistance to corrosion, high temperatures, or special operating conditions.

11.Mounting and Installation: Deep groove ball bearings are typically mounted using press fits or interference fits onto shafts or housings. Proper installation techniques, including proper alignment and preload adjustment, are crucial to ensure optimal performance and prevent premature failure of the bearings.

12.Lubrication: Proper lubrication is essential for the reliable operation and longevity of deep groove ball bearings. They can be lubricated with grease or oil, depending on the application requirements and operating conditions. Lubrication helps to reduce friction, dissipate heat, and prevent metal-to-metal contact, thereby minimizing wear and extending the service life of the bearings.

13.Quality Assurance: Manufacturers of deep groove ball bearings adhere to strict quality control standards to ensure consistent product quality and performance. Quality assurance measures may include rigorous testing, inspection of raw materials, and adherence to international standards and certifications, such as ISO 9001.

14.Specialized Variants: In addition to standard deep groove ball bearings, specialized variants are available to meet specific application requirements. These include sealed or shielded bearings for enhanced protection against contamination, high-temperature bearings for operating in extreme heat, and precision bearings for applications requiring tight tolerances and high-speed performance.

15.Maintenance: While deep groove ball bearings are known for their low maintenance requirements, periodic inspection and relubrication may be necessary to maintain optimal performance over time. Regular maintenance practices, such as checking for signs of wear or damage, monitoring operating conditions, and replenishing lubricant as needed, can help extend the service life of the bearings and prevent unexpected downtime.

In summary, deep groove ball bearings offer a wide range of features and characteristics that make them indispensable components in countless applications across various industries. Their versatility, reliability, and ease of maintenance make them a preferred choice for engineers and designers seeking efficient and cost-effective solutions for rotating machinery and equipment.