Bearing sizes

Importance of Bearing Dimensions

Compatibility: Matching the dimensions of the bearing to the shaft and housing ensures a proper fit and alignment, minimizing friction and wear.

Load Distribution: The dimensions of the bearing directly impact its load-bearing capacity and ability to distribute loads evenly, which is essential for preventing premature failure.

Interchangeability: Standardized bearing dimensions allow for interchangeability between different manufacturers and models, simplifying maintenance and replacement procedures.

Performance: Correct bearing dimensions contribute to smooth operation, reduced vibration, and enhanced efficiency of machinery and equipment.

Measurement and Specification of Bearing Dimensions

Bearing dimensions are typically specified according to international standards set by organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). Manufacturers provide detailed specifications and diagrams outlining the dimensions of each bearing model, including tolerances and deviations to ensure accuracy and consistency.

Bearing sizes play a crucial role in various industries where rotational motion is involved. From machinery to automotive applications, the correct sizing of bearings is essential for ensuring optimal performance and longevity. In this article, we’ll delve into the world of bearing sizes, covering everything from their importance to the selection process and maintenance.

Introduction to Bearing Sizes

Bearing sizes refer to the dimensions and specifications of bearings, which are mechanical components that reduce friction between moving parts and support radial or axial loads. These sizes are critical as they determine the compatibility and effectiveness of bearings within different systems.

Factors Influencing Bearing Size

Several factors influence the selection of bearing sizes, such as load capacity, speed requirements, and environmental conditions. For instance, heavy-duty machinery may require larger bearings to withstand greater loads.

Types of Bearings

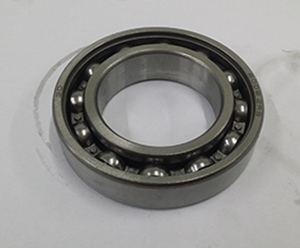

There are various types of bearings, including ball bearings, roller bearings, plain bearings, and thrust bearings. Each type has its unique design and characteristics, influencing the required size for specific applications.

Common Bearing Sizes

Standard bearing sizes are widely available and commonly used across industries. However, there are also non-standard and custom sizes tailored to specific requirements and applications.

Importance of Proper Bearing Sizing

Correct bearing sizing is crucial for optimal performance and efficiency. Improper sizing can lead to premature failure, increased friction, and reduced lifespan, affecting the overall functionality of machinery and equipment.

Selection Process for Bearing Sizes

Selecting the right bearing size involves calculations and considerations based on factors like load distribution and operating conditions. Various tools and resources, including bearing catalogs and online calculators, aid in this process.

Techniques for Bearing Size Measurement

Accurate measurement of bearing sizes is essential during installation, replacement, or maintenance procedures. Methods such as calipers, micrometers, and gauge blocks are commonly used for precise measurements.

Trends in Bearing Sizing Technology

Advancements in technology have led to innovations in bearing size measurement and selection. Digital tools and predictive maintenance systems enable more efficient and accurate sizing processes.

Future of Bearing Sizes

The future of bearing sizes is likely to involve further advancements in materials, design, and technology. These developments aim to enhance performance, durability, and reliability across various industries.

Bearing Size Maintenance

Regular maintenance is necessary to ensure bearings continue to operate effectively. Monitoring for signs of wear, lubrication, and proper alignment are key aspects of bearing size maintenance.

Conclusion

In conclusion, bearing sizes play a vital role in the functionality and performance of machinery and equipment. Understanding the factors influencing sizing, selecting the appropriate size, and maintaining bearings are crucial for optimal operation and longevity.

About us

DFL Group is based on Hebei DFL Minmet Refractories Corp. Includes Hebei DFL Minmet Refractories Corp., Hong Kong CODO company, NSAR IND LLC in U.S.A., NSAR bearing manufacturing factory and a number of NSAR brand designated manufacturers. Our brands include NSAR, 3D, OWO, CBQ, and NASA .

NSAR bearings management team of managers, engineers, and technical staff have 15 – 25 years experience. We supply customers with bearings not only produced in our own factory, but also produced in professional bearings plants designated by NSAR brand to meet customers’ different requirements, such as pillow block bearings,we have designated a factory in northern China, which has perfect testing equipment and can develop products to customer needs very rapidly. Miniature bearings are arranged in the factory in southern China, which has enjoyed a good reputation long term in producing miniature bearings.

As a professional factory that produces professional products, with professional people doing professional things, our foreign customers have declared: “NSAR bearings have reached a domestic first-class and international brand-name quality, and NSAR bearing prices are 30-50% lower than international similar bearings.”

NSAR, a professional deep groove ball bearings supplier in China, provides a broad variety of deep groove ball bearings with best customer service and quality assured. With more than 20 years deep groove ball bearings manufacture experience, our deep groove ball bearing has been exported to United States, Canada, Mexico, Brazil, Argentina.NSAR can satisfy your bulk deep groove ball bearing customization needs,We provide 6012 bearing and 6000 bearings series and 6200 bearings series and pillow block ball bearings and 6300 bearing,you can products download.