Deep groove ball bearings play a vital role in ensuring the smooth and reliable operation of machinery in various industries. These bearings are designed to reduce friction and support axial and radial loads, making them essential components in everything from household appliances to heavy industrial machinery.

Understanding Deep Groove Ball Bearings

What Are Deep Groove Ball Bearings?

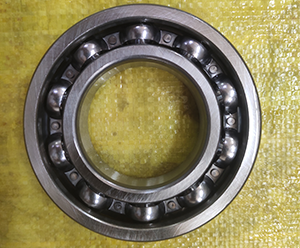

Deep groove ball bearings are a type of rolling-element bearing known for their ability to accommodate both radial and axial loads. They are called “deep groove” because of the raceway grooves that are machined into the inner and outer rings of the bearing. These grooves enable the bearing to handle a wide range of loads and rotational speeds.

The Anatomy of a Deep Groove Ball Bearing

A typical deep groove ball bearing consists of several key components:

. Inner Ring

. Outer Ring

. Balls

. Cage

. Shields or Seals

Each of these components plays a crucial role in the bearing’s functionality, ensuring smooth rotation and reduced friction.

6205 Deep Groove Ball Bearings

Features and Specifications

The 6205 deep groove ball bearing is one of the most commonly used bearings in the world. It features a bore diameter of 25mm, an outer diameter of 52mm, and a width of 15mm. Its popularity is attributed to its versatility and excellent performance.

Applications and Industries

6205 bearings find applications in a wide range of industries, including:

. Automotive

. Agriculture

. Electrical Motors

. Household Appliances

6200 Deep Groove Ball Bearings

Exploring the 6200 Series

The 6200 series includes a range of deep groove ball bearings with various dimensions and specifications. These bearings are known for their affordability and wide availability. They are often used in light to moderate load applications.

Advantages and Common Uses

6200 bearings are preferred for applications such as:

. Ceiling Fans

. Power Tools

. Conveyors

. Blowers

6308 Deep Groove Ball Bearings

The Versatile 6308 Model

6308 bearings have a bore diameter of 40mm, an outer diameter of 90mm, and a width of 23mm. They are highly versatile and are used in applications requiring moderate to heavy radial loads.

Performance and Applications

Common applications for 6308 bearings include:

. Pumps

. Gearboxes

. Textile Machinery

. Agricultural Equipment

6203 Deep Groove Ball Bearings

Unraveling the 6203 Variant

The 6203 deep groove ball bearing is known for its small size and reliability. It has a bore diameter of 17mm, an outer diameter of 40mm, and a width of 12mm.

Where 6203 Bearings Excel

6203 bearings are commonly found in:

. Skateboards

. Exercise Equipment

. Office Equipment

. Electric Motors

Choosing the Right Deep Groove Ball Bearing

Factors to Consider

When selecting a deep groove ball bearing, consider factors like:

. Load Type

. Speed

. Operating Temperature

. Environmental Conditions

Selecting the Perfect Bearing for Your Needs

Choosing the right bearing ensures optimal performance and longevity for your application.

Installation and Maintenance

Proper Installation Techniques

Proper installation is crucial for the performance and lifespan of deep groove ball bearings. It involves factors like alignment, lubrication, and preload.

Extending Bearing Lifespan through Maintenance

Regular maintenance practices can significantly extend the lifespan of your bearings, saving you time and money in the long run.

Comparing Deep Groove Ball Bearings to Other Types

How Do They Stack Up?

Deep groove ball bearings offer distinct advantages compared to other bearing types, such as angular contact and cylindrical roller bearings.

Advantages of Deep Groove Ball Bearings

Key advantages include:

. Low Friction

. Quiet Operation

. Versatility

The Importance of Quality Bearings

Investing in Reliability

Choosing high-quality deep groove ball bearings is an investment in the long-term performance and efficiency of your machinery.

Avoiding Common Pitfalls

Low-quality bearings may result in premature failure, leading to downtime and increased maintenance costs.

Innovations in Bearing Technology

Advancements in Bearing Design

The bearing industry is continually evolving, with advancements in materials, lubrication, and sealing technologies.

What the Future Holds

As industries demand more from bearings, expect further innovations in design and performance.

Real-World Applications

Bearings in Everyday Life

From your daily appliances to the machines that power industries, deep groove ball bearings play a role in countless aspects of life.

From Appliances to Automotive

Deep groove ball bearings are found in washing machines, blenders, and even the wheels of your car.

Common FAQs about Deep Groove Ball Bearings

What are the key benefits of deep groove ball bearings?

Deep groove ball bearings offer several key benefits, including:

. Low friction, resulting in reduced energy consumption.

. Smooth and quiet operation, making them suitable for various applications.

. Versatility in accommodating both radial and axial loads.

. Durability and longevity, leading to fewer replacements and maintenance.

Can I use deep groove ball bearings in high-speed applications?

Yes, deep groove ball bearings are suitable for high-speed applications. They are designed to handle various rotational speeds while maintaining their performance and reducing friction. However, it’s crucial to select the appropriate bearing size and type to match the specific requirements of your high-speed application.

How do I ensure proper lubrication for my bearings?

Proper lubrication is essential for the optimal performance and longevity of deep groove ball bearings. It’s recommended to use the lubrication type and amount specified by the bearing manufacturer. Regularly check and replenish the lubrication, ensuring that it’s clean and of the right viscosity for your application.

Are there any eco-friendly bearing options available?

Yes, there are environmentally friendly bearing options available. Manufacturers are increasingly focused on producing bearings with materials and lubricants that are more sustainable and eco-friendly. These bearings are designed to reduce environmental impact while maintaining high performance.

What is the ideal storage method for spare bearings?

Proper storage is crucial to prevent damage or contamination of spare bearings. Store them in a clean, dry, and temperature-controlled environment. Use protective packaging and keep bearings in their original packaging until they are ready for installation. Regularly inspect and rotate spare bearings to prevent any deformation due to prolonged storage.These FAQs should provide valuable insights into deep groove ball bearings, helping you make informed decisions regarding their selection and maintenance.

Are deep groove ball bearings suitable for high-temperature applications?

Deep groove ball bearings can be used in high-temperature applications, but it’s important to choose bearings with heat-resistant materials and suitable lubricants. Some deep groove ball bearings are specially designed to withstand elevated temperatures, ensuring their continued performance and durability in such conditions.

How do I determine the right bearing size for my application?

To select the right bearing size, consider factors like the load type, load magnitude, operating speed, and the space available for the bearing. You can consult bearing manufacturer catalogs or use online calculators and software tools to help you make the appropriate selection. Additionally, consulting with bearing experts or engineers can provide valuable guidance.

Can I use deep groove ball bearings in corrosive environments?

Deep groove ball bearings can be used in corrosive environments with the proper choice of materials and sealing solutions. Stainless steel bearings or those with corrosion-resistant coatings are often preferred for applications in which exposure to moisture or corrosive substances is a concern.

What is the expected lifespan of deep groove ball bearings?

The lifespan of deep groove ball bearings can vary significantly based on factors like load, speed, lubrication, and maintenance. In general, high-quality bearings operated within their specified parameters can last many years. Regular maintenance and proper lubrication can also extend their lifespan.

Can deep groove ball bearings be used in both radial and axial applications simultaneously?

Yes, deep groove ball bearings are designed to accommodate both radial and axial loads. This makes them suitable for applications where loads act in multiple directions. It’s important to ensure that the selected bearing type and configuration match the specific demands of your application to ensure optimal performance.

How can I identify if a deep groove ball bearing needs replacement?

Signs that a deep groove ball bearing may need replacement include increased noise, vibration, or heat during operation. If you notice abnormal wear or damage to the bearing, or if there is excessive play in the bearing assembly, it’s advisable to inspect and potentially replace the bearing to prevent further damage and maintain equipment reliability.

Can deep groove ball bearings be recycled?

Deep groove ball bearings, like most metallic components, can be recycled. It’s important to follow local regulations and recycling guidelines when disposing of old or worn-out bearings. Many bearing manufacturers also have recycling programs in place to ensure responsible disposal and recycling of their products.

These additional FAQs should provide further clarity on the use, maintenance, and considerations when dealing with deep groove ball bearings in various applications.

Conclusion

In conclusion, deep groove ball bearings, including popular models like the 6205, 6200, 6308, and 6203, are indispensable components in countless applications across various industries. Their ability to reduce friction, accommodate different loads, and provide longevity makes them a reliable choice for machinery and equipment. By understanding the intricacies of these bearings, you can make informed choices that lead to improved performance, reduced maintenance, and enhanced efficiency in your applications.