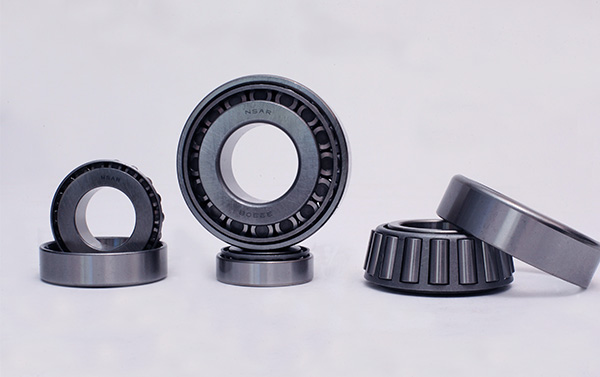

Tapered roller bearings (also called tapered bearings) are separable bearings with tapered raceways on both the inner and outer rings. They are classified into single-row, double-row and four-row roller bearings according to the number of rows of rollers. Please consult a NASR specialist for larger tapered roller bearing sizes and availability.

Categories: Tapered Roller Bearings

| Product Name: | Taper roller bearings also called car bearing such as 30207,30310,32218 etc. This type of bearings’ material is Gcr15 and quality grade can be P0,P6,P5,P4. |

Model: | 30203-30226,30303-30319,32205-32220,32305-32321, 32005-32022 etc |

| Certification: | ISO9001-2015 | Country of origin: | China |

| Material: | Gcr15 | Brand: | NSAR,3D,NASA,CBQ,OWO |

| Type: | roller bearing.Material:Gcr15;application | application: | widely used in automobile, rolling mill, mining, metallurgy and other mechanical industries. |

Tapered roller bearings (also called tapered bearings) are separable bearings with tapered raceways on both the inner and outer rings. They are classified into single-row, double-row and four-row roller bearings according to the number of rows of rollers. This bearing structure can withstand combined loads and provide low friction during operation. Rigid bearing applications can be achieved by adjusting a single-row tapered roller bearing to a second tapered roller bearing and applying a preload. Click on the product list to learn more about bearings.

The four basic components of a tapered roller bearing are the inner ring, outer ring, tapered rollers, and cage or retainer. The inner ring is mounted on the shaft, while the outer ring provides housing and support for the bearing assembly.

Low friction, noise and vibration

Long service life

Improved operational reliability even under difficult conditions

Reduced temperature peaks during the running-in period

Separable and interchangeable components facilitate easy installation, disassembly, and maintenance

Widely used in machinery industries such as automobiles, rolling mills, mining, and metallurgy.

Tapered roller bearings are used in automotive and vehicle wheel bearings, which must handle large vertical (radial) and horizontal (axial) forces simultaneously. Tapered roller bearings are typically used in medium-speed, heavy-load applications requiring durability.

Our tapered roller bearings are available in a wide range of standard industry sizes — both inch and metric types — to meet the diverse needs of global machinery applications. We offer all popular sizes and configurations, ensuring compatibility with most industrial and automotive equipment.

For large tapered roller bearings, DFL NSAR provides custom solutions designed to handle heavy loads and demanding conditions. Special sizes can be manufactured upon request to match your specific requirements. Please consult a DFL NSAR specialist for detailed specifications, lead times, and availability.

Most Preferred Uses for Tapered Roller Bearings

These bearings are typically used in heavy-duty industrial applications such as construction equipment, mining equipment, and paper mills. These bearings must be properly lubricated to ensure smooth operation and long life.

Tapered roller bearings are designed to significantly reduce friction, frictional heat, and wear, provided the bearings are properly mounted and lubricated. Tapered roller bearings are designed to be separable, with components of the same size bearing interchangeable. Tapered roller bearings significantly reduce dimensional and running tolerances for optimal load distribution. Stress peaks are avoided, which reduces material loading. As a result, tapered roller bearings are characterized by smoother operation and lower noise.

Tapered roller bearings are adjustable and removable, making installation easy.

Tapered roller bearings are available in various designs and can be customized to meet your specific speed, load, contamination, temperature, or vibration conditions.

The product information you want to know:

Copyright © NSAR Bearings. All rights reserved. Privacy Policy