Categories: Rod End Bearings

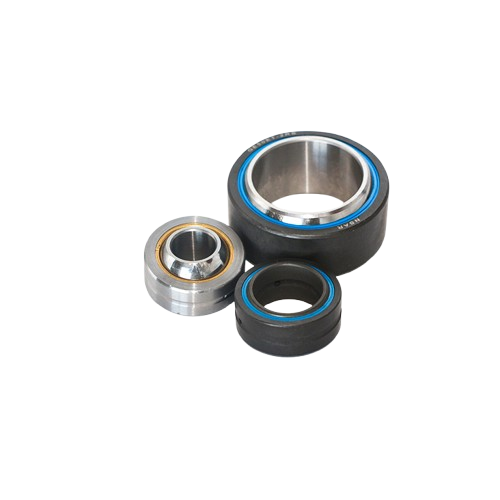

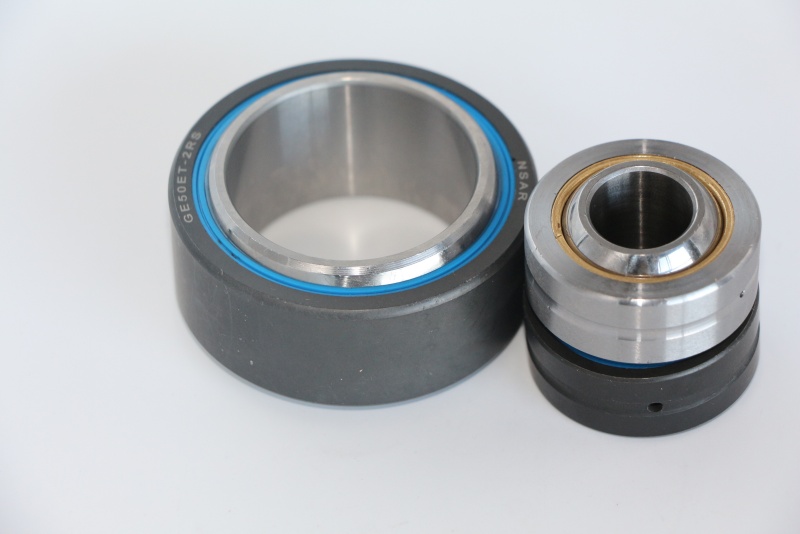

Spherical Plain Bearings are manufactured in a wide variety of materials to provide a bearing solution for almost any operating environment. NSAR Bearings offers a full range of inch and metric spherical bearings. These high-quality spherical plain bearings are suitable for heavy-duty off-highway vehicles, agricultural equipment, construction and mining and logging equipment, packaging and textile equipment, and robotics. Standard industrial bore sizes for plain bearings are 0.5 inches to 12 inches, and metric sizes are 4 to 300 mm. Custom sizes can also be ordered.

Radial spherical plain bearings have a spherical convex outer surface on the inner ring and a corresponding spherical but concave inner surface on the outer ring. Their design makes them particularly suitable for bearing arrangements that must accommodate alignment movements between shaft and housing, or must allow oscillating or repetitive tilting or slewing movements at relatively slow sliding speeds. They are available with different sliding contact surface combinations, i.e. the sliding surfaces of the inner and outer rings are made of different materials. View our general purpose bearing category.

Maintenance-required radial spherical plain bearings are available with outer rings made from hardened carbon-chrome steel or carbon steel. Bearings made from hardened chrome-carbon steel will have either axial or radial openings to accommodate the entry of the ball. The carbon steel outer ring will be pressed around the inner ring. The inner ring of maintenance-required spherical plain bearings is made from hardened carbon-chrome steel.

The sliding surfaces between these types of spherical plain bearings can be made from molybdenum disulfide (MoS 2 ), hard chrome plating, or bronze bushings to reduce wear. The outer and inner rings can be phosphate coated for increased corrosion resistance. These bearings are equipped with annular grooves and lubrication holes. Some bearing designs can also be fitted with seals to prevent contamination.

Variations with multiple split outer rings can be fitted with retaining rings. Spacers and extended inner rings are also available, please contact NSAR engineers for assistance.

Spherical plain bearings are designed to carry high loads while allowing angular motion, making them an indispensable bearing in a variety of industrial applications. These bearings are ideal for environments where reliable performance is required under misalignment, axial, and radial loads. Here are some of the key applications where spherical plain bearings are commonly used:

Construction Machinery

Spherical plain bearings are widely used in construction equipment such as excavators, bulldozers and cranes. These bearings support pivot points in hydraulic cylinders and load arms, where misalignment and high axial forces are common. Their ability to withstand harsh conditions, including dust, dirt and heavy loads, ensures reliability and longevity in construction machinery in harsh environments.

![]()

Agricultural Equipment

In the agricultural sector, spherical plain bearings are used in tractors, harvesters and tillage equipment. These bearings are often installed in steering and suspension systems, helping to absorb misalignment and vibration. Their tolerance to moisture, dirt and high pressure makes them an essential component for agricultural machinery that works in rugged and wet conditions.

Mining and Earthmoving Machinery

Mining equipment such as drills, conveyor systems and shovels rely on spherical plain bearings to withstand extreme loads and high impact forces. These bearings enable precise movement while reducing wear, making them ideal for the rough and abrasive conditions encountered in mining and earthmoving operations. They are particularly useful in applications that require high resistance to corrosion and dirt contamination.

Automotive and Heavy Vehicles

In the automotive industry, spherical plain bearings are used in suspension systems, steering mechanisms, and control arms, which can experience angular misalignment during operation. They provide smooth, controlled movement, even under high loads and temperatures, ensuring vehicle safety and stability. Heavy-duty trucks and buses also employ these bearings in chassis and drivetrains for increased durability and reduced maintenance.

Aerospace

Spherical plain bearings are essential in the aerospace industry, especially in landing gear systems, control links, and flaps. These bearings allow for necessary angular movement while withstanding extreme conditions of high altitudes and temperature fluctuations. Their lightweight yet rugged design ensures precise control of aircraft, making them a necessity for flight safety and performance.

Marine Applications

In marine environments, spherical plain bearings are used in rudder and steering systems, capstans, and other critical components exposed to seawater. Their corrosion-resistant properties make them ideal for ensuring smooth operation in both saltwater and freshwater conditions, where the ability to carry both axial and radial loads is critical.

Copyright © NSAR Bearings. All rights reserved. Privacy Policy