Metal bearings

Metal bearings are essential components used in various industries to facilitate smooth and efficient motion between two parts, reducing friction and wear. These bearings are commonly made from metals such as steel, bronze, or other alloys, depending on the specific application requirements.

Steel bearings, particularly those made from high-quality stainless steel, are popular due to their durability, corrosion resistance, and strength. Stainless steel bearings are commonly used in harsh environments where corrosion is a concern, such as in marine applications or chemical processing plants.

Bronze bearings, on the other hand, are known for their excellent wear resistance and ability to withstand heavy loads. They are often used in applications where lubrication may be challenging or in situations where the bearing needs to operate in dirty or abrasive environments.

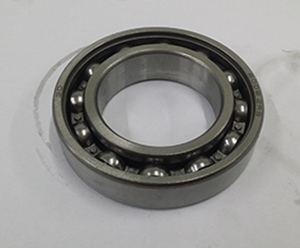

Metal bearings come in various types, including ball bearings, roller bearings, and plain bearings. Ball bearings consist of small metal balls sandwiched between inner and outer rings, while roller bearings use cylindrical or tapered rollers to facilitate motion. Plain bearings, also known as bushings, involve a sliding surface between two metal components.

When seeking metal bearings, it’s essential to consider factors such as load capacity, rotational speed, operating temperature, and environmental conditions. Choosing the right type of metal bearing for your application is crucial for optimal performance and longevity.

Whether you are in the automotive, aerospace, manufacturing, or any other industry requiring metal bearings, consulting with a knowledgeable supplier or distributor can help you select the most suitable bearings for your specific needs.

In the selection of metal bearings, understanding the specific requirements of your application is paramount. Different types of metal bearings excel in distinct conditions, and a careful evaluation ensures that you choose bearings that can withstand the demands of your equipment.

Steel ball bearings, for example, are commonly employed in applications where precision and high rotational speeds are critical. Their design allows for reduced friction and smooth operation, making them suitable for a wide range of machinery, from electric motors to industrial equipment.

Bronze bearings, with their self-lubricating properties, are often chosen for applications where regular maintenance or lubrication may be challenging. This makes them suitable for use in areas with limited accessibility or in equipment where minimizing downtime is crucial.

The proper installation and maintenance of metal bearings are also crucial for ensuring optimal performance and longevity. Adequate lubrication, periodic inspections, and adherence to recommended operating conditions contribute to the reliability and efficiency of the bearings over time.

When searching for metal bearings, it’s advisable to work with reputable suppliers who can provide guidance on material selection, bearing type, and other technical considerations. Suppliers with a diverse product range and a track record of delivering high-quality bearings can offer assurance that the chosen components will meet the specific demands of your application.

In summary, the world of metal bearings is vast and diverse, offering solutions for a wide array of industries and applications. Selecting the right type of metal bearing and maintaining it properly are essential steps in ensuring the smooth operation and longevity of machinery and equipment.

NSAR, as best 6300 bearings supplier, wholesale deep groove ball bearings, inlcuding wholesale 6308 bearings, wholesale 6307 bearing, 6306 bearings, wholesale 6305 bearing, 6304 bearings, 6302 bearings, 6309 bearings, 6311 bearings and deep groove ball bearings for household appliance and micro-motors supplies wholesale needs,products download.