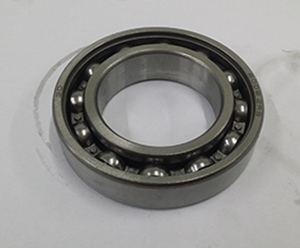

Single row deep groove ball bearing

Here are key characteristics and considerations regarding single-row deep groove ball bearings:

Design:

Deep Groove: As the name suggests, these bearings have a deep raceway that allows them to accommodate both radial and axial loads. The deep groove contributes to their ability to handle higher speeds and a wide range of loads.

Single-Row Configuration: Single-row design means that the bearing consists of a single set of balls and one inner and one outer ring. This design is suitable for applications with relatively light to moderate radial loads.

Components:

Inner and Outer Rings:

The inner ring fits onto the shaft, and the outer ring is typically housed in the bearing housing. Both rings have grooves that form the raceway for the balls.

Balls:

The balls, usually made of steel or ceramic, roll along the raceway, facilitating smooth rotation and distributing the load evenly.

Cage:

A cage, often made of steel, plastic, or brass, maintains proper spacing between the balls, preventing contact and ensuring smooth operation.

Applications:

Common Use: Single-row deep groove ball bearings are found in a wide range of applications, including electric motors, household appliances, automotive components, industrial machinery, and more.

High-Speed Operations:

Their design makes them suitable for high-speed operations, making them essential in applications where rotational speed is a critical factor.

Advantages:

Versatility: Single-row deep groove ball bearings are versatile, able to handle both radial and axial loads in a variety of applications.

Efficiency: The deep groove design reduces friction, contributing to energy efficiency and longer bearing life.

Low Maintenance: These bearings are often low-maintenance, requiring periodic lubrication to ensure optimal performance.

Considerations:

Load Ratings: It’s important to consider the load ratings of the bearing to ensure it can handle the specific loads in a given application.

Temperature: Like any bearing, operating within the temperature limits is crucial for optimal performance and longevity.

single-row deep groove ball bearings:

Installation and Maintenance:

Proper Installation: Correct installation is essential for optimal performance. This involves ensuring proper alignment, appropriate clearance, and the right amount of preload.

Maintenance: Regular maintenance includes monitoring for signs of wear, checking lubrication levels, and addressing any issues promptly. Proper maintenance helps extend the lifespan of single-row deep groove ball bearings and prevents unexpected failures.

Advanced Technologies:

Ongoing advancements in bearing technology continue to enhance the performance of single-row deep groove ball bearings. This includes innovations in materials, lubrication methods, and sealing mechanisms to improve reliability and efficiency.

Specialized Designs:

Manufacturers often offer specialized designs to meet specific application requirements. This can include high-temperature bearings, bearings with increased corrosion resistance, or precision bearings for applications demanding high accuracy.

Advantages in Specific Applications:

Electric Motors: Single-row deep groove ball bearings are commonly used in electric motors due to their ability to handle radial loads generated during rotation and axial loads when the motor is subject to thrust forces.

Automotive Applications: In the automotive industry, these bearings are found in various components, including wheel hubs, transmissions, and alternators, due to their versatility and ability to handle different types of loads.

Compact Design:

The compact design of single-row deep groove ball bearings makes them suitable for applications where space is limited. This is especially important in modern machinery and devices with compact designs.

Energy Efficiency:

The low friction characteristic of deep groove ball bearings contributes to energy efficiency in rotating systems.

This is particularly relevant in applications where minimizing energy consumption is a priority.

In conclusion, single-row deep groove ball bearings continue to be essential components in various industries, contributing to the reliable and efficient operation of machinery and equipment.

Their straightforward design, coupled with advancements in technology, ensures that they remain a cornerstone in the field of bearings.

NSAR, a professional 6000 bearing supplier in China, provides a broad variety of 6000 bearing with best customer service and quality assured. With more than 20 years 6000 bearing manufacture experience, our 6000 bearings has been exported to United States, Canada, Mexico, Brazil, Argentina. NSAR can satisfy your bulk 6000 deep groove ball bearings customization needs,We provide 6012 bearing and 6200 bearings series and 6300 bearing.you can products download.