The use of lubricants between the moving and stationary elements of mechanical equipment helps prevent damage. But when equipment is under high pressure, lubricants tend to escape, so oil seals are needed to prevent dry parts from colliding. Almost all mechanical equipment, including automotive engines, assembly machines, and PTFE machined parts, use these oil seals to prevent harmful interactions that can cause component damage.Contact NASR for your oil seal needs.

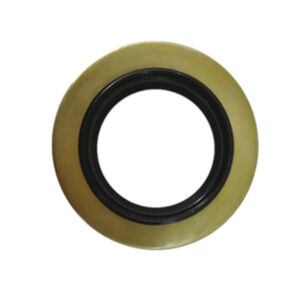

Oil seals are essential to keep lubricants and other necessary substances inside rotating shaft equipment and prevent debris from entering. Also called rotary shaft seals, shaft seals, lip seals, or elastomeric seals, these valuable devices protect the bearings of rotating shafts. Simply put, oil seals form a protective barrier that separates the inside from the outside.

How do oil seals work?

How is the oil well sealed?

What is the service life of an oil seal?

How do oil seals prevent leaks?

Oil sealswork by forming a retaining plug on the shaft. All oil seals consist of three basic components:

Inner sealing element: This flexible lip fits securely to the rotating component to prevent leakage of shaft contents. It typically requires some form of lubricant to avoid overheating.

Solid round metal housing: The housing fits over the housing to hold the seal in place.

Tension spring: The spring maintains pressure to press the sealing lip against the shaft.

When selecting an oil seal for a shaft, many factors must be considered. These factors include temperature, size, shaft speed, pressure, lubrication availability, and environment. Each setup is unique, and a proper fit is critical to ensure the oil seal remains in place and effectively protects the bearing. A custom molded oil seal is often required to provide a superior fit and increased durability.

Contact the bearing manufacturer!

While selecting a quality, custom oil seal can greatly extend the life of your equipment, many other factors can affect the life of the part. These include:

Condition of the shaft and bearing cavity: Any sharp edges or burrs can cause premature damage or even ruin a new seal immediately.

Seal Material: What a seal is made of has a big impact on its durability.

Installation and Maintenance: Adequate lubrication, fit and regular inspection can extend the life of an oil seal.

Operating Conditions: Extreme temperatures, excessive pressure or exposure to chemicals can cause premature failure of parts.

There is currently no accurate way to predict the life of an oil seal due to the complexity of the factors involved.

Oil seals have a flexible inner lip that presses securely onto the shaft. Springs maintain pressure and a solid metal housing holds the unit firmly in place. When optimally installed and in good condition, the oil seal forms a protective seal around the shaft, protecting the internal components.

A lot – too many to mention, covering a wide range of designs, sizes and materials for endless applications. Some designs are made to international standards such as BS1399 and DIN 3760 for metric sizes and seal types, but most are manufactured to suit specific applications – so there is a wide range to choose from. This blog is designed to assist you in making your selection and will considerseal type, material and size.

The easiest way is to know the preferred manufacturer’s part number, overall dimensions of shaft diameter, housing diameter and bore depth, or use our brochure to establish an ordering reference. In this age of “takeovers” many of the traditional seal manufacturer names have either changed or have disappeared. If they are no longer available we will advise you and, whenever possible, provide a suitable replacement seal from stock. If your concern is getting the right seal for the job you will need to know a little about the application as well as the overall dimensions. If you have any questions – please contact us and we will help you select a seal.

Leather is probably the oldest lip material still in widespread use today, but with the development of mass production methods there has been a huge growth in the development of synthetic rubbers that are suitable for precise and repeatable injection and compression molding. Nitrile (NBR) remains the most common elastomer in “conventional” use, while Viton® (FKM/FPM) is rapidly replacing polyacrylate (ACM) and silicone (VMQ) in high temperature applications. Viton® also has strong abrasion and chemical resistance making it the elastomer of choice. The use of PTFE in rotary shaft seals has recently attracted a lot of attention, especially in applications with high-speed shaft rotation or poor lubrication.

NSAR has more than 20 years of experience in oil seal and bearing production. Contact us to order your bearings.

Copyright © Rolamentos NSAR. Todos os direitos reservados.